MAIL US

devcoat@devcoatings.co.in

CALL US

+91 9819304488

Catalysts

Catalytic hydrogenation is undoubtedly the most useful and widely applicable method for the reduction of chemical substances and has found numerous applications in organic synthesis in research laboratories and industrial processes.

We supply International Quality at Competitive Prices.

Copper Chromite

Catalytic hydrogenation is the most useful and widely applicable method for the reduction of chemical substances and has found numerous applications in organic synthesis in research laboratories and industrial processes. Copper chromite is an industrially important catalyst because of its ability to hydrogenate functional groups in aliphatic and aromatic compounds selectively. Hydrogenation of edible oils - The catalysts are usually charged into the oil in the oxidized form and are partly reduced to Cu(I) and/or Cu (0) during use.

Hydrogenation of aromatic compounds - Selective hydrogenation of aromatic nitro groups to the corresponding aromatic amines is one of the most important reactions.

Hydrogenation of Alcohols and aldehydes at a temperature of 125-150 C.

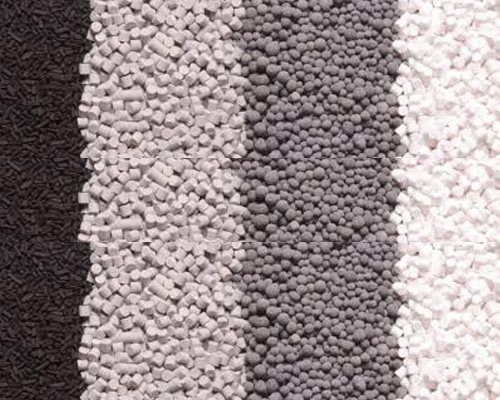

This catalyst is available in powder and tablet form.

Nickle Catalyst

This is used as a reagent and as a catalyst in organic chemistry. Hydrogenation – to treat with hydrogen – is a chemical reaction between molecular hydrogen (H2) and another compound or element, usually in the presence of a Nickel catalyst. The process is commonly employed to reduce or saturate organic compounds.

This catalyst is available in pellet and extrude form.

Copper Catalyst

This is used for removal impurities and Oxygen from Nitrogen thereby delivering quality inert gases. It helps remove the sulfur, arsenic, chlorine and other impurities to 0.2 to 0.5 ppm.

This catalyst is available in tablet form.

Sulphur Absorption

Removal of ‘Sulphur’ compounds from hydrocarbon feedstock is one of the most essential criteria for further processing of these hydrocarbons. This Catalyst is available as extruded as 3, 4 and 5 mm diameter size range.

Chloride Absorption

Modified Alumina based catalyst, with optimum surface area, with good crush strength is used for Organic chloride removal from feedstock in hydrocarbon. This Catalyst is available as extruded as 3, 4 and 5 mm diameter size range.

Activated Alumina

Applications –

- Especially suited for compressed air-drying systems.

- Very stable physical & chemically, even in high temperature and corrosive environment.

- Arsenic & Fluoride removal from ground water.

- Peroxide removal from Organic Solvent Tetrahydrofuran (THF)

- Acid removal – Transformer oils, Lubricating Oils & Refrigerants all from degradation acids upon use.

- Primarily used for air drying & low temperature application for getting better dew point.

- A highly efficient absorbent with large porosity and contact surface.

- Extremely effective for drying gases.

- Primarily used for air drying & low temperature application for getting better dew point.

- Form and sizes- Extrude, (5-8 mm) Ball (3-5mm & 5-8mm) & powder form

Raney Nickel

Application- Raney Nickel with Promoters/Raney nickel for desulphurization

- Nitro to Amino, & oxime to amine

- Debenzylation ring hydrogenation & carbonyl to alcohol

- Aldehyde to alcohol

- Saturation of olefinic double bond

- Dehydrogenation

- Dextrose to sorbitol

- Ammonlysis of alcohol

- Nitriles to amines with higher recycles.

Customized Catalyst

Available as per customer requirements.

Get in Touch

+91 9819304488

+ 91 22 62169000 TO 30 (30 LINES)

1127, Hubtown solaris,

N S Phadke Road,

Andheri East

Mumbai 400069.

Quick Links

All Rights Reserved By Dev Coatings & Catalysts LLP | Designed By Mirackle Solutions